Product Life Cycle

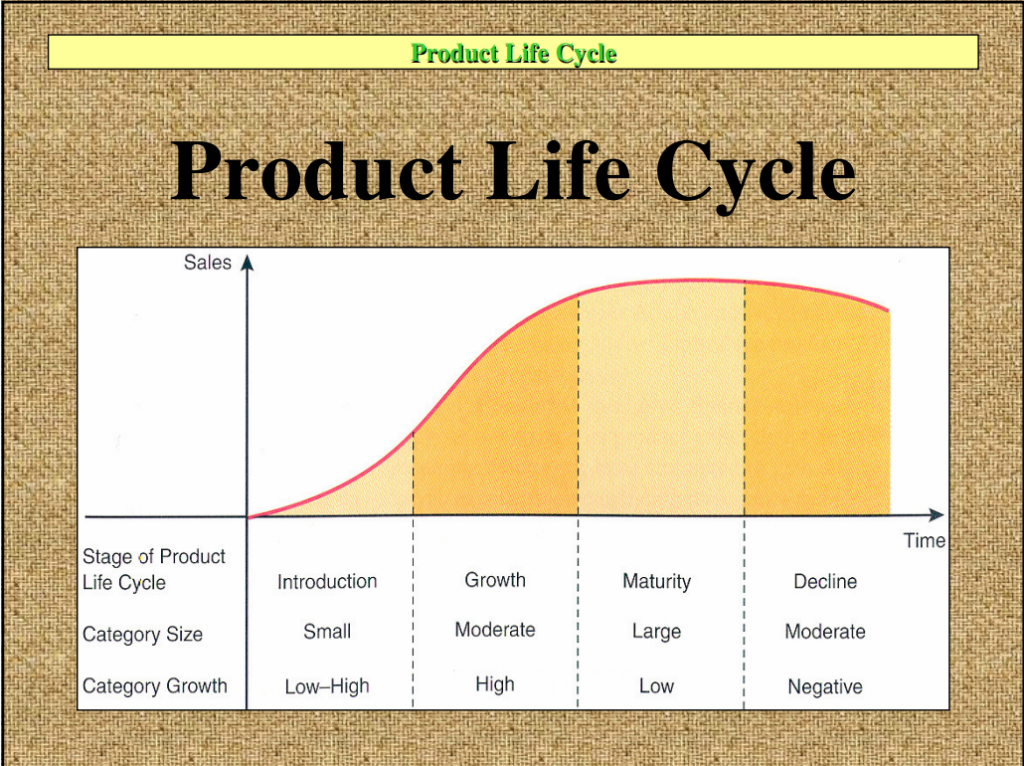

The Product Life Cycle is a fundamental concept in marketing that describes the stages a product goes through from when it first enters the market until it is removed from the market. The stages typically include introduction, growth, maturity, and decline.

A product has a life of its own and goes through cycles. Although different products have different

Ag Decision Maker

types of life cycles, the traditional product life cycle for most products is shown in image.

extension.iastate.edu/agdm

If you are considering entering an industry and making a product, knowing where the product is in its life cycle can provide valuable information of how to position your product in the market in terms of price, promotion, and distribution. Products typically go through four stages during their lifetime. Each stage is different and requires marketing strategies unique to the stage.

Introduction Stage

This stage involves introducing a new and previously unknown product to buyers. Sales are small, the production process is new, and cost reductions through economies of size or the experience curve have not been realized. The promotion plan is geared to acquainting buyers with the product. The pricing plan is focused on first-time buyers and enticing them to try the product.

Growth Stage

In this stage, sales grow rapidly. Buyers have become acquainted with the product and are willing to buy it. New buyers enter the market and previous buyers come back as repeat buyers. Production may need to be ramped up quickly and may require a large infusion of capital and expertise into the business. Cost reductions occur as the business moves down the experience curve and economies of size are realized. Profit margins are often large. Competitors may enter the market but little rivalry exists because the market is growing rapidly. Promotion and pricing strategies are revised to take advantage of the growing industry.

Maturity Stage

In this stage, the market becomes saturated. Production has caught up with demand and demand growth has slowed precipitously. There are few first-time buyers. Most buyers are repeat buyers. Competition becomes intense, leading to aggressive promotional and pricing programs to capture market share from competitors or just to maintain market share. Although experience curves and size economies are achieved, intense pricing programs often lead to smaller profit margins. Although companies try to differentiate their products, the products actually become more standardized.

Decline Stage

In this stage, buyers move on to other products and sales drop. Intense rivalry exists among competitors. Profits dry up because of narrow profit margins and declining sales. Some businesses leave the industry. The remaining businesses try to revive interest in the product. If they are successful, sales may begin to grow. If not, sales will stabilize or continue to decline.

Understanding the product life cycle can help businesses make data-driven decisions and strategize effectively. It’s important to note that not all products follow the same life cycle. Some products may remain in the maturity stage for a long time, while others may move from introduction to decline rapidly.

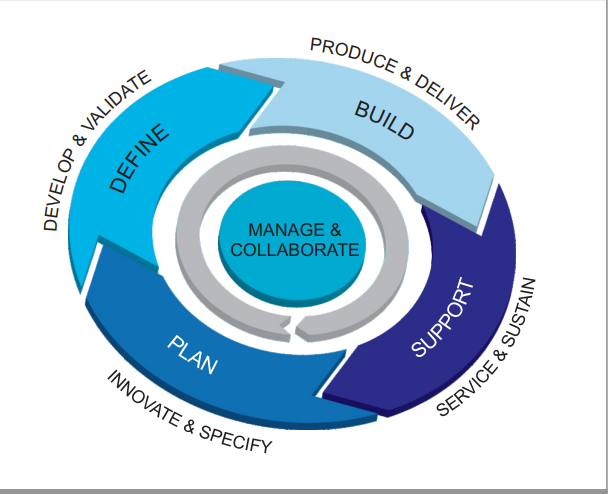

Product Life Cycle Management

Product lifecycle management is the process of managing the entire lifecycle of a product from its conception, through design and manufacture, to service, and disposal. PLM integrates people, data, processes, and business systems and provides a product information backbone for companies and their extended enterprise. It can be represented as shown below.

LM is one of the four cornerstones of a corporation’s information technology structure. All companies need to manage communications and information with:

- Their customers through Customer Relationship Management (CRM) and their suppliers (Supply Chain

Management or SCM), - Their resources within the enterprise (enterprise resource planning or ERP)

- And planning (systems development lifecycle or SDLC).

- In addition, manufacturing engineering companies must also develop, describe, manage and communicate

information about their products (PLM).

History of PLM

Inspiration for the burgeoning business process now known as PLM came when American Motors Corporation (AMC) was looking for a way to speed up its product development process to compete better against its larger competitors. In 1985, AMC began development of a new model, that later came out as the Jeep Grand Cherokee. The first part in its quest for faster product development was a computer-aided design (CAD) software system that makes engineers more productive.

The second part in this effort was the new communication system that allowed conflicts to be resolved faster, as well as reducing costly engineering changes because all drawings and documents were in a central database. The product data management was so effective that after AMC was purchased by Chrysler, the system was expanded throughout the enterprise connecting everyone involved in designing and building products.

As an early adopter of PDM technology, Chrysler was able to become the auto industry’s lowest cost producer, recording development costs that were half of the industry average by the mid-1990s. This innovation motivated the software companies and the OEM’s to invest in the development of various CAD and PDM tools.

Some of the milestones in evolution of PDM/PLM include:

1960’s: New display methods and equipment, first CADD draft and design applications, sketchpads and light pens bring innovation into the design process

1970’s: Introduction of CAD/CAM systems, automated 2D drafting, first independent production workstations

1980’s: PC systems were born into the real word, introducing 3D systems, PDM problematic grows up on importance

1990’s: Parametric CAD/CAM/CAE systems integrates together with other PLM components, global market brings large PLM systems cooperation through all over the word, HW components prices and introducing IT systems rapidly grows the CAx/PLM market area

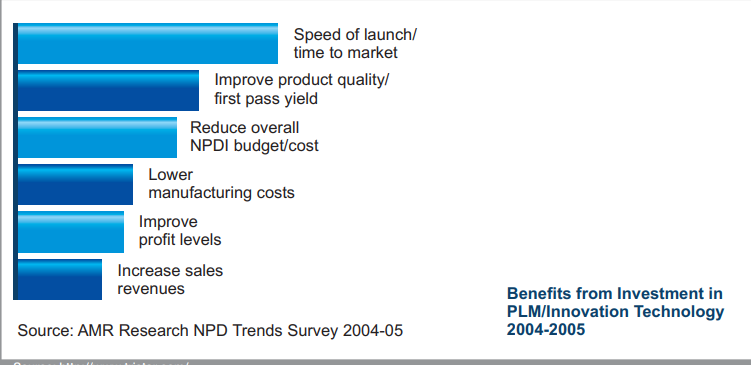

Profit from Innovation:

PLM extends the advantages of design automation beyond product design to achieve higher levels of corporate benefits. PLM leads to corporate value by extending design information and processes across multiple organizations and implementing consistent corporate processes and control. PLM enables collaboration that allows people to work together more effectively to increase innovation and leverage it appropriately.

PLM can also enable corporate initiatives such as strategic sourcing, eliminating undesirable raw materials for regulatory or “green” purposes, or reducing proliferation of raw materials that lead to increased inventory, and overhead costs. In short, PLM has proven value in helping companies harness innovation for profits. The ongoing success of a company is strongly linked to how effectively it can capture and leverage its intellectual property and product-related knowledge; PLM also provides value as the corporate “repository” for product information.

- Reduced time to market: PLM optimizes design cycle efforts through immediate and managed access to all the historical design data that can be reused in new designs

- Improved product quality: Product quality is improved because of tight integration of customer, product, quality and regulatory information within a closed-loop corrective action system

- Reduced prototyping costs: Re-use of existing data will lower the cost of new prototypes

- Savings through the complete integration of engineering workflows: The time taken for global workflow process is very much saved with PLM

- Faster release cycles of products

- Reduced design times: New designs take lesser time in a PLM environment because of the digital workflow

- Faster deployment and rollout of new products: The evaluation of a product from concept stage to

manufacturing stage is very much controlled and automated which results in faster rollout of new products - Reduced administrative overheads: PLM simplifies the development or production process. When

subjected to external audit for certifications, a PLM product can simplify review and acceptance.

Product Life Cycle Examples

Apple’s iPhone is a great example of a product life cycle. Since its introduction in 2007, the iPhone has gone through the stages of the product life cycle. It saw rapid growth with widespread market acceptance, then reached maturity where updates and new features helped sustain sales. As newer technologies emerge, the iPhone will eventually reach the decline stage.

Global PLM Service Providers

Some of the PLM Service Providers available in the market are: SIEMENS PLM Services, EDS, MindTree Limited, Infosys, Satyam Computer Services Ltd. Altair, MSC Software Corp., T-Systems, Intergraph PDM Solutions, Computer Sciences Corporation, Tata Consultancy Services, PRTM, ITC InfoTech, HCL Technologies Ltd, PRION Group, Keane, Capgemini, Wipro Technologies, Accept Software Corporation, Access Commerce Inc, Access Systems LLC, Actify, Inc.,

ACS Software, Inc., Active Sensing, Inc., Agile Software, AIM systems, Allegria Software Inc., Alibre, Amadeus International, Apriso Corporation, Aras Corporation, Arena Solutions, Artemis International Solutions Corporation, Assetium Assyst Bullmer Ltd., Autodesk, Auto-trol Technology Corp., Bamboo Solutions, BigMachines, Inc., Business Management Systems, CADD Solutions Pvt Ltd, Cadman Corporation, CEIMIS Enterprises, INC., CENIT, Centric Software, Inc., Cimage NovaSoft Ltd,

Cimmetry Systems, CMstat, Coastal Logic, Inc., CoCreate Software Inc., Engineering PLM Solutions, Engineous Software, Inc., Enginuity, Enovia, EPM Technology, eQuorum Corporation, eQ Technologic, Eurostep Commercial Solutions, Exertus, FeaturePlan, Federation Software, First Trace, Inc., Formtek, Framework Technologies, Freeborders, Inc., Fujitsus, Full Circle Systems, IBM, INCAT, Intergraph, Interneer, Orcon GmbH

Future Trends in PLM

One of the known problems in any product industry (OEM’s) is that the industry consists of many departments such as business/project management, engineering department, quality control management, operations, sales etc., using their own custom software applications. Along with that, the company also uses products for ERP, CRM, SCM. and BOM management system etc.

All these applications lack interoperability among them. Because of this, whenever any decisions are taken by the organization for new products or modifying existing products, the complete data (data may be from ERP or from SCM, CRM etc.) for estimating the costs, tooling, changes, and others are not directly available even though the company uses PLM and hence the organization needs more time for obtaining all the data from various systems which impacts their product into the market. Hence there is need for a kind of architecture which can bridge all these applications and provide a common platform of application for all the departments.

One such architecture is Service Oriented Architecture (SOA).

- A service-oriented architecture is essentially a collection of services. These services are independent and can

communicate with each other. - The communication involves either simple data passing or it could involve two or more services coordinating

same activity. - SOA is an IT architecture for request – reply applications for modularizing and presented as services.

- Application functions with services are loosely coupled, and service interface is independent of implementation.

How SOA can help in PLM Integrations

The demand for loosely coupled integration is increasing day by day as new authoring tools are adding up in large enterprises and also the maintenance of legacy application integrations are becoming costly. This situation influenced major PLM vendors to introduce an SOA interface in their product architecture. Most of the OEM’s are revisiting / re-drawing their product roadmaps to make use of this SOA in their enterprise integration scenario. This is enabling the PLM systems to become an enterprise application and not restricted only to engineering data.

MphasiS PLM Practice

MphasiS is building a strong PLM Practice for catering to the fast-growing PLM market. Setting up a core group of PLM subject matter experts (SME) is a step towards developing a strong practice. The PLM Practice SME’s will be utilized to train resources on PLM skills and execute Business consulting, solution design PLM frameworks, methodologies and other activities.

The Importance of the Product Life Cycle

Understanding the product life cycle is crucial for businesses. It helps in planning and developing strategies at each stage of the life cycle. It also assists in predicting the future performance of the product.

In conclusion, the product life cycle is a vital concept in understanding the stages a product goes through in its lifespan. By understanding these stages, businesses can better strategize and make informed decisions to maximize profitability and product longevity.

Conclusions:

The need for PLM service providers is increasing year on year as the market demand for manufacturing the products with less cost and more functionalities are increasing. Implementing a PLM solution requires in depth knowledge of industry processes as well as PLM tools. The PLM products are becoming more matured and implementations need functional resources who can configure the business processes in PLM tools.

Large enterprises with multiple application integrations are now looking for consolidating their applications for operational excellence. The “SOA” a new paradigm in software architecture solutions is enabling the enterprises to revise/revisit their PLM road maps. The PLM software vendors are also re-architecting/rewriting their tools to facilitate the SOA functionalities.

The MphasiS PLM practice focuses on value-added PLM services as well as high volume high revenue services such as PLM support, maintenance, and development activities.

References for PLM information

Siemen's PLM solutions and components:

http://www.plm.automation.siemens.com/en_us/products/open/index.shtml

Oracle's Agile suite for PLM:

http://www.oracle.com/agile/index.html

IBM's PLM solution:

http://www-01.ibm.com/software/plm/

Parametric Technology:

www.ptc.com

Dassault Systèmes:

www.3ds.com

American Society of Mechanical Engineers:

www.asme.org

American Society for Quality:

www.asq.org

Association for Configuration and Data Management:

www.acdm.org

Automation.com (industrial automation, process control, and instrumentation):

www.automation.com

Engineering Automation Report:

www.eareport.com

JT Open (Jupiter Technology) data format:

www.jtopen.com

PLM Alliance (University of Michigan-Ann Arbor):

plm.engin.umich.edu

- 10 Best Essential Business Management Techniques You Need to Know

- Maximize Efficiency and Growth: Expert Product and Service Management Solutions

- Why Macroeconomics is the study of the economy as a whole – Best Info

- Understanding Supply and Demand: A Comprehensive Explanation

- The Nature and Scope of Macroeconomics- A Best Guide

What are the 7 stages of the product management life cycle?

Idea generation

Idea screening

Concept development and testing

Business analysis

Product development

Test marketing

Commercialization

What is the 5 stages of product life cycle?

Introduction

Growth

Maturity

Decline

Phase-out or Renewal

What is product lifecycle management PDF?

Product Lifecycle Management (PLM) PDF typically refers to documents, guides, or content related to managing product lifecycles using PDF (Portable Document Format) files. It may include information on integrating PLM concepts into PDF-based documentation for efficient collaboration and information sharing across different stages of a product’s lifecycle.

What is product life cycle and its management?

Product Life Cycle (PLC) is the progression of a product through various stages, from introduction to decline. Product Lifecycle Management (PLM) involves overseeing a product’s entire lifecycle, including design, development, production, and disposal.

PLC stages:

Introduction

Growth

Maturity

Decline

PLM encompasses:

Conceptualization

Design and development

Manufacturing and production

Marketing and sales

Use and maintenance

Disposal or renewal

The goal is to optimize each stage for efficiency, cost-effectiveness, and meeting customer needs.